Long Term Testing

Thursday, July 5, 2012

Rob A.

With our GP38-2 locomotives arriving any day now, some people have asked about the quality of a $100 Z scale locomotive. Traditionally locomotives in Z scale have cost from about $150 to over $200, so what corners do we cut to produce motive power for so much less?

With our GP38-2 locomotives arriving any day now, some people have asked about the quality of a $100 Z scale locomotive. Traditionally locomotives in Z scale have cost from about $150 to over $200, so what corners do we cut to produce motive power for so much less?

There are a few factors. First, the tooling for the shell comes from the old Rouge days, so it was fully paid for. That’s a huge part of the cost. Second, our newer locomotives have things like injection molded window glass, separate snow plows and brass handrails, while the GP38-2 has sheet plastic for its windows and we used POM plastic handrails. On our newer products we use an injection molded light guide to direct the LED headlight to the proper location on the locomotive – on the GP38-2 we used a piece of fiber optic cable to direct the light. These things all add up on the tooling and production cost.

But let’s also look at where we put real value into the GP38-2. Same as our newer models, our entry level GP38-2 has LED headlights, a coreless motor, traction tires, split frame design, highly detailed paint and pad printing. When you think about it, we really didn’t “cut any corners” but instead found some ways to simply deliver a solid product at a great price.

They also get thoroughly tested. I use a figure 8 “over and under” track to torture test the new locomotives. I randomly select some production locomotives and start running them, non-stop, for days and days. The figure 8 track makes sure the trucks turn to the left as much as they turn to the right. The over and under drives them both up and down grades. The lower straight section has some turnouts on it, so they run through frogs and points too. I even intentionally misaligned a few pieces of track, and I use several brands of power packs to test pure DC, pulse wave, and square pulse power.

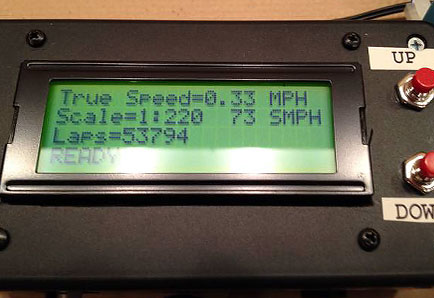

I use a digital speedometer that has two electric eye beams. The electronics know the distance between the beams, so it measures the difference of time it takes for the locomotive to break the two beams, and from that it can calculate a very precise speed.

Most of the running is done at medium power (8 volts for our models) but about 25% is run at full throttle (12 volts) and the other 25% is run slowly at about 4.5 volts. Twice a day a change in speed or direction is made so while they never stop for more than a second, they are constantly changing stresses and performance.

These locomotives run nonstop not for hours or days, but weeks and sometimes months at a time. The goal is to see how long it takes them to get to end of life. Eventually everything mechanical will fail, but the GP38-2 has been one of the best performing models we have produced to date. In fact, the GP38-2 took a few more weeks to fail than I had anticipated, which in turn caused a minor delay in product development. Once they finally fail, we can take them apart to see why the failure occurred and make improvements to the design so that it will not happen again.

So how long will you locomotive last? Well our test results are a bit of a trade secret, but we really don’t like warranty work. I’m confident I won’t see many GP38-2 come back across my desk.

Let’s Talk About This On The AZL Forum

Category: Rob's Blog